FAQ for Extremely Rugged Hoppers

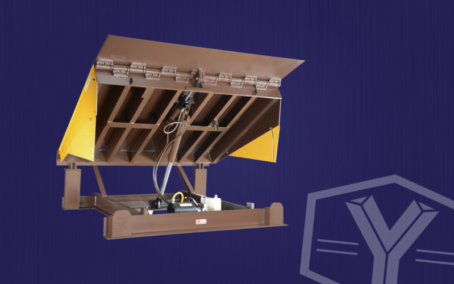

1. What are extremely rugged hoppers?

Extremely rugged hoppers are high-durability containers designed to withstand the toughest environments and heavy loads. Built with materials like steel, these hoppers are ideal for industries that require long-lasting performance and resistance to wear and tear. These hoppers can endure rough handling, harsh conditions, and heavy-duty tasks, making them perfect for demanding applications.

2. How do rugged hoppers differ from regular hoppers?

Rugged hoppers, including extremely rugged versions, are built with reinforced materials and enhanced construction to handle more extreme conditions than standard hoppers. They are designed to resist damage from impacts, heavy loads, and corrosive materials. If regular hoppers are a workhorse, extremely rugged hoppers are like the "Chuck Norris of hoppers"—tough, reliable, and built to last!

3. What are the benefits of using extremely rugged hoppers?

The main benefits of using extremely rugged hoppers include unmatched durability, reliability, and longevity. These hoppers are perfect for high-stress environments like construction sites, heavy manufacturing facilities, and waste management operations. They reduce the need for frequent replacements and can handle everything from scrap metal to harsh chemicals. Plus, they help increase safety and efficiency in your workflow.

4. What materials can steel hoppers handle?

Steel hoppers, including rugged models, can store and transport a wide variety of materials. Common contents include bulk items such as sand, gravel, scrap metal, chemicals, and waste. The versatility of rugged hoppers makes them suitable for many different industries. They're built to endure whatever materials you need to handle, from powders to liquids, and everything in between.

5. Are extremely rugged hoppers customizable?

Yes, extremely rugged hoppers can be customized to meet your specific needs. You can adjust their size, weight capacity, discharge mechanisms, and features like reinforced frames or corrosion-resistant coatings. Yankee Supply can help you tailor a rugged hopper to your operation’s exact specifications, ensuring it works as hard as you need it to.

6. How durable are rugged hoppers?

Extremely rugged hoppers are built to take a beating. Made from heavy-duty steel or similar materials, these hoppers are designed to withstand high impacts, extreme temperatures, and corrosive substances. Whether you're dealing with heavy machinery or harsh environmental conditions, these hoppers are built to endure. Heck, they’re almost as rugged as Chuck Norris' beard!

7. How can I purchase extremely rugged hoppers from Yankee Supply?

To purchase extremely rugged hoppers or to get more information about our options, contact Yankee Supply at 800.232.7225. Our team will guide you through the process and help you choose the perfect hopper to meet your operational needs.

Need an extremely rugged hopper that’s tough enough for your toughest jobs? Call Yankee Supply at 800.232.7225 today and find the perfect solution for your business!