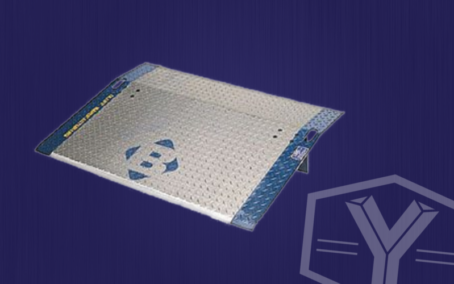

Warehouse Dock Plates: Reliable Solutions for Smooth Loading and Unloading

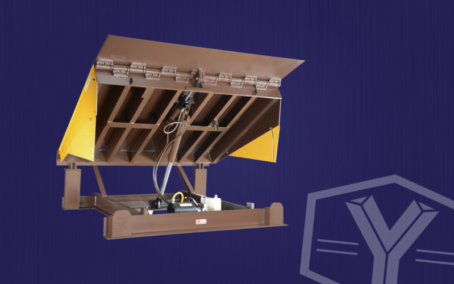

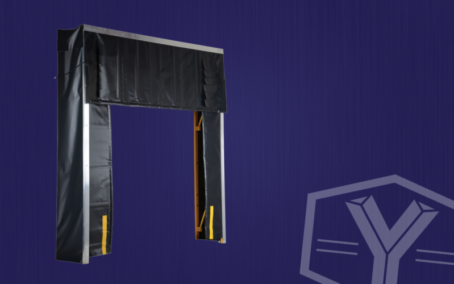

Warehouse dock plates are essential tools for ensuring smooth transitions between loading docks and trucks in commercial and industrial environments. These heavy-duty platforms act as bridges to fill the gap between a loading dock and the vehicle bed, providing a safe and stable surface for material handling. Whether you’re dealing with pallet jacks, forklifts, or other equipment, dock plates help to prevent damage to goods and vehicles while enhancing overall productivity.

Key Features of Warehouse Dock Plates

Warehouse dock plates come in a range of sizes, materials, and configurations to meet the diverse needs of your warehouse. The primary function is to level out the height difference between the dock and the truck, offering a smooth pathway for goods to be transferred with ease. Most dock plates are made from durable steel or aluminum to handle heavy loads and withstand the constant wear and tear of busy warehouses.

Dock plates are designed to accommodate different weight capacities. From lightweight models for smaller loads to heavy-duty options that can support thousands of pounds, these products are built to be reliable and sturdy. The thickness of the plate and the material composition directly contribute to its load-bearing ability. Many models also feature a treaded surface or slip-resistant coatings to enhance safety, ensuring that workers and equipment stay secure when moving goods.

Benefits of Using Warehouse Dock Plates

Warehouse dock plates are an excellent investment for any business with high-volume shipping and receiving. One of the main advantages is their ability to bridge the gap between the loading dock and trucks, eliminating dangerous or inefficient manual lifting. This makes the entire loading and unloading process quicker and more efficient, increasing overall productivity.

Additionally, warehouse dock plates help prevent damage to goods, which can be a significant cost-saving factor in the long run. Without a proper dock plate, goods may be subjected to unnecessary stress, which can lead to broken items or damage during transport. Dock plates offer a smooth, flat surface that minimizes these risks.

The versatility of warehouse dock plates cannot be overstated. With adjustable height settings and easy portability, these plates are suitable for various trucks, whether flatbed, box truck, or semi-trailer. Their ergonomic design allows workers to load and unload shipments with minimal physical strain, which in turn reduces the risk of workplace injuries.

Choosing the Right Warehouse Dock Plate

Selecting the right dock plate for your facility is crucial for safety and efficiency. Start by considering the type of material handling equipment you use. If your warehouse primarily uses forklifts, you may need a heavy-duty dock plate with a higher load capacity. For lighter tasks, a thinner, lighter model might be sufficient.

Also, pay attention to the dimensions of the dock plate to ensure it fits both your loading dock and the trucks you receive. A plate that’s too small may create gaps, while one that’s too large may not be easy to maneuver.

Conclusion

In conclusion, warehouse dock plates are indispensable tools for improving efficiency, safety, and damage prevention in warehouse operations. Their ability to create a smooth, stable connection between trucks and docks helps streamline loading and unloading processes, reducing downtime and increasing worker productivity. When choosing the right dock plate, consider your specific needs, the equipment you use, and the expected weight capacity to ensure you select a reliable solution that will stand the test of time.

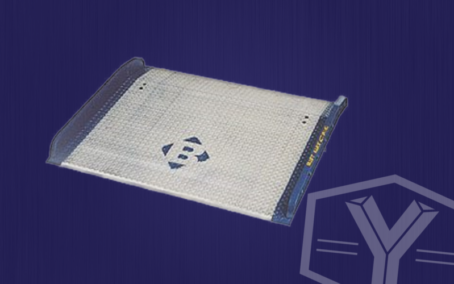

Warehouse dock plates are in stock:

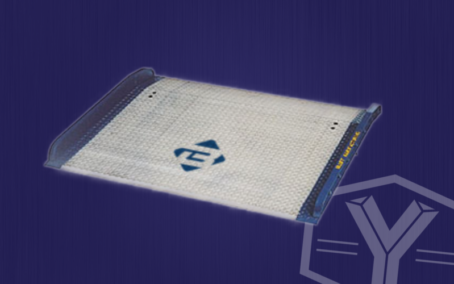

- Size: 48″ x 60″

- Price: $550.00

- Model: # A4860

Lip bend is 11 degrees. Height differential of 7″. Recommended for nonpowered loading applications. 1,656 capacity. Low-cost solution to light activity applications. Bolt-on steel legs for securing position between the dock and the trailer

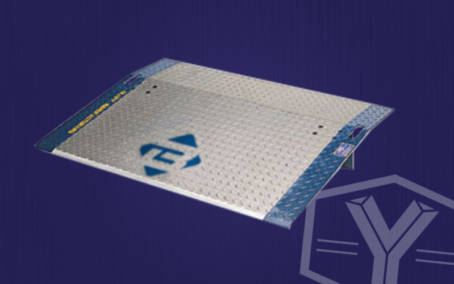

- Size: 48″w x48″L

-

Price: $460.00

- Model # A4848

Lip bend is 11 degrees. Height differential of 5″. Recommended for nonpowered loading applications. 2,388 pounds capacity. Low-cost solution to light activity applications. Bolt-on steel legs for securing position between the dock and the trailer.

- Size: 48″w x 36″L

-

Price: $375.00

- Model # A4836

Lip bend is 11 degrees. Height differential of 3″. Recommended for nonpowered loading applications. 4,383 pounds capacity. Low-cost solution to light activity applications. Bolt-on steel legs for securing position between the dock and the trailer.

For more information on these new dock plates please give us a call.