In the bustling world of warehouse management, efficiency is the name of the game. Enter teardrop pallet racking systems, the pinnacle of practical storage solutions. Crafted with precision and durability, teardrop pallet racking is engineered to maximize space utilization while streamlining warehouse operations.

At its essence, teardrop comprises sturdy teardrop uprights and beams, meticulously designed to accommodate varying pallet sizes and weights. Its distinctive teardrop-shaped perforations along the uprights facilitate swift and secure beam placement, eliminating the need for complex hardware and ensuring effortless adjustments to shelf heights.

With its robust framework, teardrop offers unparalleled stability and support, making it an ideal choice for storing a wide range of merchandise. Whether handling heavy-duty items or fragile goods, businesses can trust in the reliability of teardrop to safeguard their inventory while optimizing floor space.

In an ever-evolving business landscape, adaptability is key. Teardrop pallet racking rises to the challenge, providing a scalable solution that can grow alongside the demands of the warehouse. From small-scale storage facilities to expansive distribution centers, its modular design allows for seamless expansion, offering a cost-effective storage solution that adapts to changing needs.

Join us as we delve deeper into the advantages of teardrop, exploring its practical applications and real-world benefits for warehouse optimization. Discover why industry professionals worldwide rely on teardrop to enhance efficiency and maximize productivity in their operations.

Understanding Teardrop Pallet Racking Systems

Teardrop racking systems represent a cornerstone in the world of industrial storage solutions. Engineered for versatility and efficiency, these systems are designed to maximize warehouse space while facilitating seamless inventory management.

Identifying Teardrop Rack

Spotting teardrop is easy when you know what to look for:

- Teardrop-Shaped Holes: Check for teardrop-shaped holes along the uprights. These holes hold the teardrop beams in place, a telltale sign of teardrop rack.

- Adjustable Beams: Teardrop racks have beams that can be adjusted to fit different pallet sizes. Look for racks with versatile beam heights.

- Easy Assembly: Teardrop shelving is modular and easy to assemble. If it's simple to put together and adjust, chances are it's a teardrop rack.

- Strong Build: Quality teardrop racks are built to last. Look for sturdy construction using durable materials like steel.

- Compatible Accessories: Teardrop racks work with various accessories like wire decking and pallet supports. If it's compatible with these extras, it's likely a teardrop rack.

Keep an eye out for these features, and you'll easily spot teardrop in any warehouse setting.

What Sets Teardrop Racking Apart

At the heart of teardrop rack lies its innovative design, characterized by teardrop-shaped perforations along the uprights. These strategically placed perforations enable quick and secure beam placement, allowing for effortless adjustments to shelf heights and configurations. This unique feature eliminates the need for cumbersome hardware, streamlining the installation process and enhancing operational efficiency.

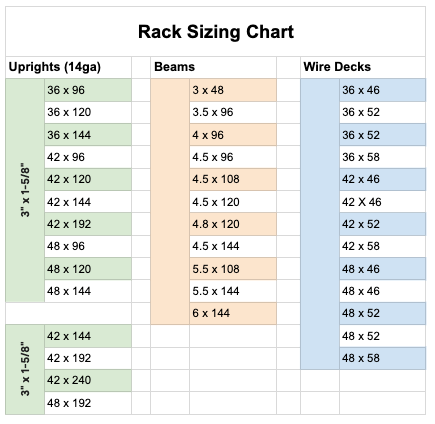

Components of Teardrop Pallet Racking

Teardrop pallet racking systems consist of two primary components: uprights and beams. The uprights serve as the vertical support structures, while the beams connect to the uprights horizontally, forming the shelves where pallets are stored. Constructed from high-quality steel, these components are built to withstand heavy loads and provide long-lasting durability in demanding warehouse environments.

Advantages of Teardrop Pallet Racking

When it comes to warehouse storage solutions, teardrop pallet racking stands out as a versatile and efficient option. Let's explore some of the key advantages that make teardrop racking systems a top choice for businesses seeking to optimize their storage space and streamline operations.

1. Space Optimization

Teardrop pallet racking systems are designed to maximize vertical space utilization, allowing businesses to make the most of their warehouse footprint. With adjustable beam heights and customizable shelf configurations, these systems can accommodate a wide range of inventory sizes and shapes, from bulky merchandise to smaller items, effectively minimizing wasted space and maximizing storage capacity.

2. Ease of Installation

One of the standout features of teardrop is its ease of installation. Unlike traditional racking systems that require extensive hardware and complex assembly processes, teardrop racking systems can be quickly and effortlessly assembled using minimal tools. This streamlined installation process saves time and labor costs, allowing businesses to get their storage facilities up and running with minimal disruption to operations.

3. Flexibility and Adaptability

Teardrop systems offer unmatched flexibility and adaptability, making it an ideal solution for businesses with evolving storage needs. With adjustable beam heights and configurable shelf configurations, these systems can be easily reconfigured to accommodate changes in inventory size, weight, or storage requirements. Whether scaling up operations or reorganizing existing space, teardrop racking systems provide the flexibility needed to adapt to changing business demands.

4. Durability and Strength

Constructed from high-quality steel, teardrop pallet racking systems are built to withstand the rigors of daily warehouse operations. The robust construction of these systems ensures long-lasting durability and strength, capable of supporting heavy loads without buckling or bending. This durability not only ensures the safety of stored inventory but also minimizes the risk of costly damage or accidents in the warehouse.

5. Cost-Effectiveness

In addition to their practical benefits, teardrop offers significant cost savings for businesses. The modular design of these systems reduces the need for expensive customizations or modifications, while the ease of installation lowers labor costs associated with setup and assembly. Furthermore, the space optimization provided by teardrop racking systems can lead to reduced real estate expenses, as businesses can make better use of existing warehouse space without the need for expansion.

6. Compatibility with Accessories

Teardrop pallet racking systems are compatible with a wide range of accessories and add-ons, allowing businesses to further customize their storage solutions to meet specific requirements. From wire decking and pallet supports to safety accessories and aisle signage, businesses can enhance the functionality and safety of their teardrop racking systems with ease.

7. Scalability for Future Growth

As businesses evolve and expand, the scalability of teardrop pallet racking becomes increasingly valuable. These systems can be easily expanded or reconfigured to accommodate changing storage requirements, providing a cost-effective solution for long-term growth and optimization.

In summary, teardrop systems offer a versatile, efficient, and adaptable solution for warehouse storage needs. With their innovative design, durable construction, and ease of installation, these systems are trusted by industry professionals worldwide to enhance warehouse efficiency and productivity.

Applications of Teardrop Pallet Racking

Teardrop pallet racking is a versatile storage solution with a wide range of applications across various industries. Let's explore some common uses for teardrop pallet racking and how it benefits different sectors:

Warehousing

In warehousing and distribution centers, teardrop pallet racks play a vital role in efficiently storing and organizing products and materials. Whether handling bulk items or smaller packages, teardrop racking systems provide the flexibility and scalability needed to meet the demands of modern warehousing operations.

Manufacturing

Manufacturing facilities rely on teardrop systems to store raw materials, components, and finished products. With adjustable beam heights and customizable shelf configurations, teardrop racking systems offer the versatility needed to accommodate a wide range of inventory types and sizes, streamlining the manufacturing process and optimizing workflow efficiency.

Retail

Retail stores utilize teardrop to store and display a variety of products, including clothing, electronics, and sporting goods. The sturdy construction and adjustable design of teardrop racking systems make them well-suited for retail environments, where space optimization and product visibility are essential for driving sales and enhancing the customer experience.

Automotive

In automotive facilities, teardrop rack is used to store and organize parts, tools, and equipment. From engine components to tires and accessories, teardrop racking systems provide a reliable storage solution that helps automotive professionals maintain efficient inventory management and streamline their operations.

Food and Beverage

Food and beverage facilities rely on teardrop to store ingredients, finished products, and packaging materials. With strict hygiene and safety requirements, these facilities require storage solutions that are durable, easy to clean, and resistant to corrosion. Teardrop racking systems meet these criteria, making them an ideal choice for food and beverage storage applications.

Pharmaceuticals

Pharmaceutical facilities use teardrop to store raw materials, finished products, and packaging materials. With stringent regulatory requirements and the need for precise inventory management, pharmaceutical companies require storage solutions that offer both reliability and efficiency. Teardrop racking systems provide the necessary stability and organization to meet these demands, ensuring compliance and product integrity.

E-commerce

In e-commerce fulfillment centers, teardrop is essential for storing and organizing products for shipping. With the rapid growth of online shopping, e-commerce companies require efficient storage solutions that can handle high volumes of inventory while maximizing warehouse space. Teardrop racking systems offer the scalability and flexibility needed to meet the evolving demands of the e-commerce industry, enabling businesses to fulfill orders quickly and accurately.

In summary, teardrop pallet racking is a versatile storage solution that finds applications in a wide range of industries, from warehousing and manufacturing to retail, automotive, food and beverage, pharmaceuticals, and e-commerce. With its adaptability, durability, and efficiency, teardrop racking systems play a crucial role in optimizing storage space and enhancing operational efficiency across various sectors.

Teardrop Also Known As

Teardrop pallet racking, also known as selective rack, goes by various names in the industry. Here are alternative names you might encounter:

- Universal pallet rack

- Quick Pick Rack

- Interlock pallet rack

- Slotted pallet rack

- T-bolt pallet rack

- Keystone pallet rack

- Boltless pallet rack

These terms are often used interchangeably to refer to the same versatile storage solution. Whether you hear it called universal pallet rack or quick pick rack, rest assured that it's still the reliable and efficient teardrop pallet racking system.

Teardrop Pallet Racking Manufacturers

Teardrop pallet racking, a popular storage solution, is manufactured by several reputable companies. Here are some of the leading manufacturers in the industry:

- Yankee Supply Company: Known for its quality teardrop pallet racking line, Yankee Supply Company offers reliable and durable storage solutions tailored to meet various warehouse needs.

- Husky Rack & Wire: With a reputation for excellence, Husky Rack & Wire manufactures teardrop racking systems known for their strength, durability, and ease of installation.

- Interlake Mecalux: A global leader in warehouse storage solutions, Interlake Mecalux produces teardrop systems renowned for their innovative design and superior performance.

- Steel King: Steel King is recognized for its robust and versatile teardrop systems, designed to withstand heavy loads and optimize warehouse space.

- Ridg-U-Rak: Ridg-U-Rak manufactures high-quality teardrop solutions known for their durability, reliability, and compatibility with various warehouse applications.

- Speedrack: Speedrack specializes in teardrop systems designed to maximize storage space and improve warehouse efficiency.

- Frazier Industrial Company: Frazier Industrial Company offers a wide range of teardrop solutions known for their durability, flexibility, and customization options.

- Unarco Material Handling, Inc.: Unarco Material Handling, Inc. manufactures teardrop systems designed to meet the diverse storage needs of warehouses and distribution centers.

- Penco Products, Inc.: Penco Products, Inc. is a trusted manufacturer of teardrop pallet racking systems known for their reliability, durability, and ease of installation.

- Prest: Prest is a leading supplier of teardrop rack, known for their high-quality construction and cost-effective solutions.

- Hannibal Industries: Hannibal Industries produces teardrop systems known for their innovative design, superior strength, and long-lasting performance.

These manufacturers are committed to providing top-quality teardrop pallet racking solutions that meet the diverse needs of warehouse operators worldwide. With their extensive experience and dedication to excellence, they continue to set the standard for reliable and efficient storage solutions in the industry.

In conclusion, teardrop pallet racking systems stand as a cornerstone in the realm of warehouse storage solutions. Their versatility, durability, and efficiency make them indispensable tools for businesses seeking to optimize their storage space and streamline operations. With a wide range of applications across various industries and trusted manufacturers committed to excellence, teardrop racking continues to be the go-to choice for warehouse managers worldwide.

As businesses evolve and grow, the scalability and adaptability of teardrop racking ensure that it remains a valuable asset for long-term storage needs. Whether it's for warehousing, manufacturing, retail, or other sectors, teardrop racking systems provide the foundation for efficient and organized storage solutions, ensuring smooth operations and maximizing productivity. Consider investing in teardrop racking to elevate your warehouse storage capabilities and unlock the potential for growth and efficiency, especially in scenarios such as double deep pallet racking systems.