Streamline Waste Management with Forklift Dumpster Hoppers

Waste management often poses a significant challenge in the relentless pursuit of efficiency in industrial operations. Enter forklift dumpster hoppers, the rugged solution to revolutionize waste handling processes. Let's delve into what makes these hoppers indispensable for warehouse managers and industrial professionals.

Efficient Waste Disposal with Forklift Dumpster Hoppers

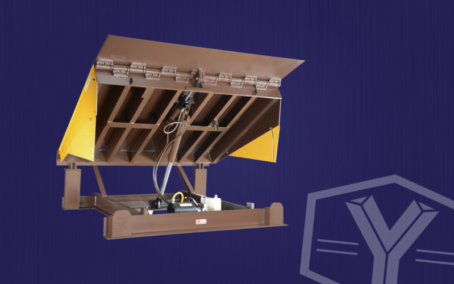

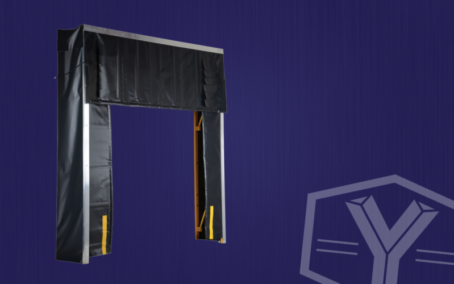

Forklift dumpster hoppers are versatile receptacles specifically engineered to integrate seamlessly with forklifts, offering a convenient and efficient method for disposing waste materials. Featuring an automatic dumping mechanism activated by a bumper release, these hoppers effortlessly empty their contents into dumpsters with a simple maneuver. Equipped with safety restraints and manual cable operation options, they prioritize both efficiency and worker safety.

Benefits and Features

Effortless Dumping

With the innovative bumper release mechanism, Dumpster hoppers ensure effortless dumping of waste materials. The hopper automatically tips forward when it contacts the front of the dumpster, allowing for quick and efficient disposal without requiring manual intervention.

Enhanced Safety Measures

Safety is paramount in any industrial setting, and forklift dumpster hoppers are designed with this principle in mind. From automatic return to upright and locked positions after dumping to the inclusion of safety restraints, these hoppers prioritize the well-being of workers and minimize the risk of accidents during the waste disposal process.

OSHA Compliance

Self-dumping forklift hoppers facilitate compliance with OSHA General Industry regulations, particularly rule 29 CFR 1910.178(m)(5)(iii). By allowing forklift operators to remain at the controls throughout the dumping process, these hoppers ensure adherence to safety guidelines and regulatory standards.

Versatile and Stackable Design

Dumpster hoppers offer unparalleled versatility in waste management operations, featuring usable fork pockets and a stackable configuration. With any of the models, these hoppers can be easily stacked for efficient storage and transport, optimizing space utilization in warehouses and industrial facilities.

Streamlining Waste Management Across Industries

Forklift dumpster hoppers find widespread application across various industries where efficient waste management is essential. From manufacturing facilities and distribution centers to construction sites and retail warehouses, these hoppers streamline waste-handling processes, increasing productivity and operational efficiency.

Empowering Efficiency: The Impact of Forklift Dumpster Hoppers

In industrial operations' fast-paced and demanding environment, every tool and equipment plays a critical role in driving efficiency and productivity. Forklift dumpster hoppers may seem like a small component in the grand scheme of warehouse management, but their impact is insignificant. With their effortless dumping capabilities, enhanced safety features, and versatile design, these hoppers empower warehouse managers to tackle waste management challenges head-on, ensuring a cleaner, safer, and more efficient workplace environment.