Durable and Reliable Material Handling Solutions

Industrial steel hoppers are essential tools for businesses that need to efficiently handle and transport bulk materials in various industries, including manufacturing, construction, agriculture, and waste management. Designed to withstand harsh environments and heavy-duty use, steel hoppers offer a reliable and long-lasting solution for storing, moving, and disposing of materials. Whether you need to store loose materials, unload bulk items, or transfer waste, industrial steel hoppers are the ideal choice for enhancing operational efficiency and maintaining a smooth workflow.

What Are Industrial Steel Hoppers?

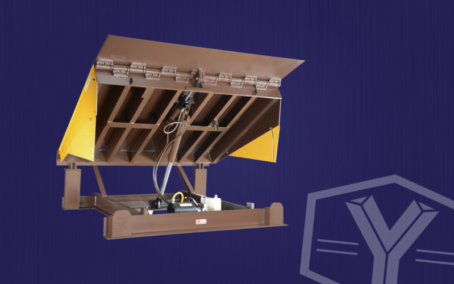

Industrial hoppers are large, robust containers typically made from high-strength steel, designed to hold and transport bulk materials. They come in various shapes and sizes, including open-top and funnel-bottom models, to suit different material handling needs. Steel hoppers are often used in industrial settings to store items such as sand, gravel, scrap metal, coal, grain, or waste. The material’s design helps ensure the efficient flow of goods, allowing for quick loading, unloading, and movement within warehouses, factories, or construction sites.

The steel construction of these hoppers provides the strength and durability needed to handle heavy loads and resist wear from abrasive materials. Additionally, the corrosion-resistant properties of steel make these hoppers ideal for outdoor use or in environments where exposure to moisture or chemicals is common.

Benefits of Industrial Steel Hoppers

1. Durability and Strength: One of the key advantages of industrial steel hoppers is their durability. Made from high-quality steel, they can withstand the stress of heavy loads, rough handling, and harsh weather conditions. This durability ensures that your investment in steel hoppers lasts for many years, providing excellent long-term value.

2. Versatility in Use: Steel hoppers are incredibly versatile and can be used in a wide range of industries and applications. From storing materials in factories to transporting waste in construction sites, they are designed to handle a variety of bulk goods. Many models are designed with features such as built-in lifting hooks, drop gates, and smooth edges to facilitate easy loading and unloading, making them adaptable to different tasks.

3. Easy Handling and Movement: Industrial steel hoppers are equipped with durable wheels or casters, making them easy to move and position as needed. This mobility allows workers to quickly transport materials between different areas of a facility, improving workflow and reducing labor time. Many hoppers also come with options for being moved by forklift, which adds even more flexibility to their use.

4. Cost-Effective Solution: Hopper containers provide a cost-effective solution for bulk material handling. Their sturdy design reduces the need for frequent repairs or replacements, minimizing downtime and repair costs. Additionally, their versatility allows them to be used across a range of operations, eliminating the need for multiple types of containers for different materials.

5. Safety Features: Many industrial hoppers come equipped with safety features such as locking mechanisms, secure lids, or guardrails to prevent accidental spills or materials from falling out. These features help protect workers from potential hazards and ensure a safer working environment.

Applications of Steel Hoppers

Industrial steel hoppers are widely used in industries that handle bulk materials. In manufacturing, they are used to store raw materials like sand, gravel, or metal scrap. In agriculture, hoppers store and transport grains, seeds, or fertilizers. Construction sites rely on steel hoppers to move debris or construction waste efficiently. They are also commonly used in the mining and waste management industries for storing and transporting materials in bulk quantities.

Conclusion

Industrial steel hoppers are an indispensable tool for efficient and safe material handling in industrial settings. Their strength, durability, and versatility make them ideal for a wide range of applications, from construction sites to warehouses to manufacturing plants. Whether you're storing bulk materials, moving waste, or handling raw goods, steel hoppers provide a reliable, cost-effective solution for your material handling needs. With their robust design, easy mobility, and long-lasting performance, steel hoppers are a smart investment for businesses looking to enhance efficiency and improve workflow.