All-Welded Self Dumping Hoppers: Enhancing Industrial Efficiency

In the dynamic landscape of industrial operations, efficiency is paramount. All-welded self dumping hoppers stand as reliable workhorses, efficiently handling bulk materials and scrap generated in manufacturing processes. Let's delve into why these hoppers are essential for your operational success.

Streamlined Handling for Maximum Efficiency

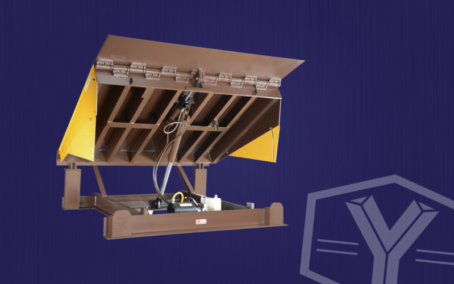

Designed for practicality, these hoppers provide seamless handling of materials, whether bulk or scrap. Easily maneuverable with a forklift or optional casters, they ensure swift transportation within your facility. The narrow models, crafted for tight spaces, maintain load capacity without sacrificing efficiency. Stackable and shippable in tandem, they optimize logistics and space utilization.

Secure and Controlled Material Disposal

The one-piece trip handle with a positive locking mechanism ensures secure material handling. Engineered to dump when the locking handle is tripped, these hoppers return to an upright locked position when empty. This gravity-centric design facilitates controlled material discharge, enhancing overall safety and operational precision.

Standard Safety Features for a Secure Work Environment

Prioritizing safety, these hoppers come equipped with standard features that include a safety retaining chain, remote trip rope assembly, safety labels, safety latch, and a high-visibility vista green color. These elements contribute to a secure work environment, aligning with the practical needs of industrial professionals.

Benefits & Features

Optimal Space Utilization

The ingeniously narrow design of these self-dumping hoppers proves to be a game-changer, effortlessly fitting into tight spaces without the slightest compromise on load capacity. This thoughtful engineering translates to an exceptional ability for efficient space utilization, making these hoppers ideal for deployment in warehouses and manufacturing facilities where every square inch matters. The streamlined design not only ensures practicality but also enhances overall storage efficiency.

Controlled Material Discharge

At the heart of these self dumping hoppers lies a gravity-centric design that goes beyond the ordinary. It orchestrates a meticulously controlled and secure material discharge process, significantly minimizing operational risks while maximizing overall efficiency. This innovative approach to material handling isn't just about emptying the hopper; it's about doing so in a manner that ensures precision and safety. The result is a seamless workflow where each step is a testament to the optimization of operational processes.

Swift Maneuverability

When it comes to the movement of bulk materials within industrial settings, these self dumping hoppers take the lead with unparalleled ease. Whether it's a forklift or optional casters, the versatility of these hoppers allows for swift and hassle-free transportation. The agility they offer is a testament to their engineering excellence, catering to the need for efficiency in handling materials. This ease of movement not only enhances the speed of operations but also contributes to an overall smoother workflow within the industrial environment.

Industry Use Cases

All-welded self dumping hoppers find invaluable applications across various industries, addressing material handling challenges effectively.

Manufacturing Processes

In the intricate realm of manufacturing processes, these self dumping hoppers emerge as indispensable assets, enabling the efficient management of bulk materials and the handling of scrap generated during various production stages. Their seamless integration ensures a meticulously streamlined workflow on the bustling factory floor, where the optimization of material handling becomes a pivotal factor in enhancing overall operational efficiency.

Warehousing

Tailored to meet the demands of warehouses, these self dumping hoppers transcend conventional solutions by not only optimizing space usage but also revolutionizing logistics within industrial storage facilities. Their versatility proves instrumental in creating an environment where every inch of space is maximized, contributing significantly to the seamless operation and organization of large-scale warehouses. As a result, these hoppers redefine the standards for efficiency in warehousing practices.

Construction Sites

In the challenging landscape of construction sites, these self dumping hoppers emerge as the go-to solution for efficiently managing construction debris and waste materials. Their adaptability addresses the unique challenges posed by construction environments, providing practical and effective solutions. The result is a harmonious blend of functionality and efficiency, making these hoppers the perfect companion for construction sites where the demands on material handling are both diverse and demanding.

Closing Thoughts

Investing in all-welded self dumping hoppers is a strategic move to elevate the efficiency of your material handling operations. With features focused on practicality, safety, and seamless operation, these hoppers cater to the needs of professionals managing warehouses and industrial facilities. Upgrade your material handling capabilities with this reliable solution designed for real-world industrial efficiency.