Optimizing Load Security With Pallet Wrappers

Pallet wrappers are an essential tool for industrial operations that require secure, efficient load stabilization. Designed to streamline the packaging process, these machines wrap pallets tightly with stretch film, ensuring that products remain intact during storage and transit. By automating this process, stretch wrap machines improve efficiency, reduce waste, and help protect goods from damage caused by shifting or environmental factors.

Enhancing Load Stability And Protection

The primary function of pallet wrappers is to ensure that palletized loads are stable and secure. By applying a consistent layer of stretch film, these machines prevent products from shifting during handling or transportation. This level of stability is especially important for fragile items, irregularly shaped goods, or heavy loads. Wrappers also provide an added layer of protection against dust, moisture, and debris, safeguarding shipments until they reach their destination.

Increasing Efficiency In Packaging

Manually wrapping pallets can be time-consuming and labor-intensive, making stretch wrappers an invaluable asset for high-volume operations. These machines automate the wrapping process, allowing workers to complete tasks faster and with less physical effort. With programmable settings, wrappers can adjust to accommodate different load sizes, film tension levels, and wrap patterns. This versatility ensures that each pallet is wrapped efficiently, saving time and reducing labor costs.

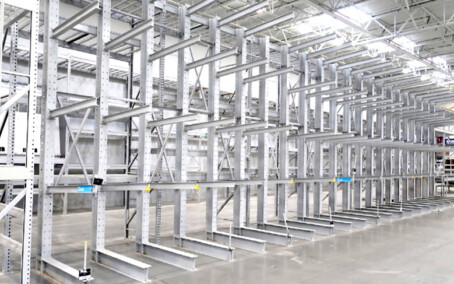

Durability For Demanding Environments

Industrial environments demand durable and reliable equipment, and pallet wrappers are built to meet these expectations. Constructed from robust materials, these machines are designed to handle continuous operation in warehouses, distribution centers, and manufacturing facilities. Their heavy-duty components ensure consistent performance, even under demanding conditions. Routine maintenance, such as checking rollers or replacing film dispensers, keeps these machines operating at peak efficiency for years.

Customizable Options For Diverse Needs

Pallet wrappers are available in a variety of models to suit different operational requirements. Turntable wrappers, orbital wrappers, and robotic wrappers each offer unique advantages, making it easy to find a solution tailored to specific applications. Adjustable features, such as variable wrap speeds or film pre-stretch capabilities, allow businesses to customize their wrapping process for optimal results. Whether handling lightweight packages or oversized loads, these machines provide the flexibility needed to achieve consistent outcomes.

Cost Savings And Waste Reduction

Investing in pallet wrappers can lead to significant cost savings over time. Automated wrapping ensures that film is applied uniformly, minimizing waste caused by manual errors or overuse. By reducing the amount of stretch film required for each pallet, businesses can lower material costs while maintaining secure loads. Additionally, the reduced risk of damaged goods during transit minimizes financial losses and improves customer satisfaction.

Supporting Scalable Growth

As operations expand, pallet wrappers offer the scalability to keep up with increasing demands. Their ability to handle a wide range of load types and volumes makes them an adaptable solution for growing businesses. Whether wrapping a few pallets a day or managing large-scale shipping operations, these machines ensure that loads are prepared efficiently and securely.

Pallet wrappers provide a comprehensive solution for improving load stability, enhancing productivity, and reducing packaging waste. By automating the wrapping process, businesses can increase efficiency, protect goods, and support sustainable practices in their supply chain operations. For any facility looking to optimize its palletizing workflow, wrapping machines are a reliable and cost-effective choice.