Essential Protection for Your Facility

Warehouse guardrails are a critical safety feature designed to protect both employees and inventory within warehouse environments. These durable barriers provide vital protection from accidents and damage caused by forklifts, machinery, or other equipment. Whether you're safeguarding high-traffic areas, protecting storage spaces, or securing hazardous zones, guardrails deliver the safety and security your facility needs to run efficiently.

What Are Warehouse Guardrails?

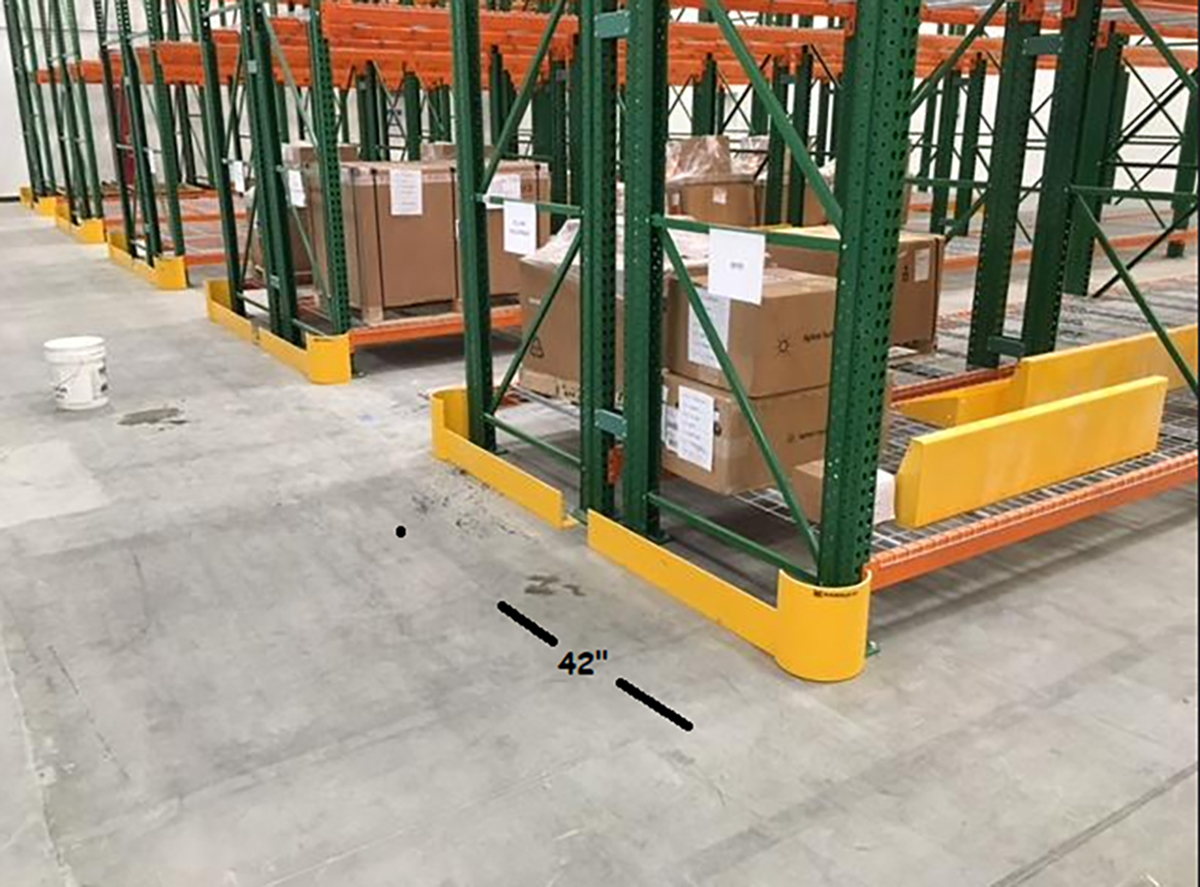

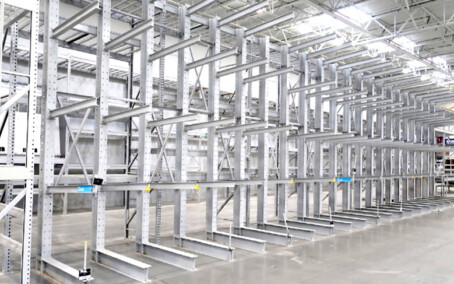

Guardrails are heavy-duty, industrial-strength barriers made from materials like steel or other tough alloys. They are strategically placed throughout a warehouse to offer physical protection in areas where accidents are more likely to occur. These rails are typically installed around high-traffic zones, pallet racking systems, loading docks, and walkways. The purpose of warehouse guardrails is to create a barrier that prevents collisions, safeguards both workers and equipment, and helps manage traffic flow in busy environments.

By utilizing gravity and impact-absorbing materials, guardrails can help prevent accidents and protect valuable assets. The installation of these rails is an effective and straightforward way to enhance warehouse safety without requiring complex changes to existing infrastructure. Their simple design ensures that warehouse operations can continue smoothly while minimizing the risk of costly accidents or downtime.

Benefits of Warehouse Guardrails

1. Improved Safety: The primary benefit of railing is its ability to enhance safety within a facility. By acting as a barrier, these rails protect workers from potential collisions with machinery and vehicles such as forklifts and pallet jacks. They also help define pedestrian walkways and vehicle paths, reducing the chances of accidents and injuries.

2. Protection of Inventory: Warehouse guardrails not only protect employees but also safeguard valuable inventory and equipment. When installed around shelving units or storage areas, these rails act as a shield, preventing forklifts and other vehicles from accidentally damaging goods or racking systems. This reduces the risk of costly damages to products and inventory.

3. Efficient Traffic Flow: In high-traffic areas where forklifts, pallet jacks, and workers are constantly moving, railing helps manage the flow of equipment and personnel. They create clear divisions between pedestrian and vehicle zones, reducing congestion and improving overall workflow. With less interference and confusion, operations become more streamlined and efficient, which can ultimately reduce delays and increase productivity.

4. Durability and Longevity: Warehouse guardrails are built to withstand the physical demands of a busy industrial environment. Constructed from high-quality materials, these rails are designed to endure heavy impacts, constant use, and harsh conditions. This durability ensures that your investment in guardrails pays off over time, as they require minimal maintenance and offer long-lasting protection.

5. Easy to Install and Maintain: Warehouse guardrails are designed for quick installation, often requiring minimal tools and labor. Once in place, these rails are low-maintenance, with few moving parts and a simple structure. The durability of the materials used ensures that guardrails can withstand years of wear and tear, making them a cost-effective solution for long-term warehouse safety.

Applications of Warehouse Guardrails

Warehouse guardrails are essential in a variety of industries, including logistics, manufacturing, retail, and distribution. These rails are particularly useful in facilities with high-traffic areas, such as loading docks, aisles, and around pallet racking systems. By providing clear boundaries and physical protection, they help to prevent accidents, improve efficiency, and ensure the safety of workers and goods.

In conclusion, warehouse guardrails are an indispensable component of any industrial or warehouse facility. With their ability to improve safety, protect inventory, and streamline warehouse operations, these rails offer significant benefits to both businesses and employees. Installing guardrails throughout your facility not only helps prevent accidents but also creates a more organized, efficient workspace. Investing in warehouse guardrails is a smart decision for companies looking to safeguard both their people and their products.