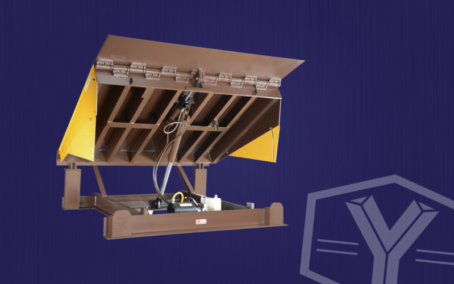

Push back racking is a dynamic warehousing solution designed to maximize storage capacity and streamline inventory management processes. Unlike traditional static shelving systems, push back utilizes a unique gravity-fed design, allowing for deep-lane storage of multiple pallets. This innovative system is ideal for warehouses and distribution centers seeking to optimize space utilization without compromising accessibility.

In a push back pallet racking system, pallets are loaded onto nested carts that glide along inclined rails within the racking structure. As new pallets are added, previously loaded pallets are pushed back deeper into the storage lane, hence the name "push back." This dynamic arrangement enables high-density storage of goods while maintaining efficient picking and retrieval operations.

Push back rack systems are highly versatile, accommodating various pallet sizes and weights, making them suitable for a wide range of industries and applications. Whether storing perishable goods in a cold storage facility or managing bulk inventory in a manufacturing plant, push back offers flexibility and scalability to meet diverse storage needs.

With its space-saving design and intuitive operation, push back racks deliver several key benefits to warehouse operators. From increased storage capacity to enhanced inventory visibility, this system provides a cost-effective solution for optimizing warehouse space and improving operational efficiency.

In the following sections, we will delve deeper into the features, advantages, and applications of push back, shedding light on why it has become a preferred choice for modern warehouse management.

About Push Back Racking

Push back warehouse racking, also known as dynamic racking, revolutionizes warehouse storage by offering a high-density solution that maximizes space utilization. Unlike conventional pallet racking systems, push back employs a Last-In, First-Out (LIFO) inventory management approach, allowing for efficient rotation of goods while optimizing storage capacity.

Efficient Space Utilization

One of the primary advantages of push back racking is its ability to make the most of available warehouse space. By utilizing a deep-lane storage configuration, this system allows multiple pallets to be stored within each storage lane, minimizing wasted space and maximizing storage density. As a result, warehouses can accommodate a larger inventory without the need for expansion, ultimately reducing overhead costs associated with additional storage facilities.

Dynamic Storage

Push back racking offers dynamic storage capabilities, enabling warehouse operators to easily adjust inventory levels and storage configurations as needed. With its gravity-fed design, pallets are automatically pushed back into the racking system as new pallets are loaded, ensuring optimal space utilization while facilitating efficient inventory management. This dynamic storage solution enhances operational flexibility, allowing warehouses to adapt to changing inventory demands and seasonal fluctuations with ease.

Enhanced Accessibility

Despite its high-density storage capabilities, push back racking maintains excellent accessibility to stored goods. Unlike drive-in racking systems, which require operators to enter storage lanes for pallet retrieval, push back allows for full access to each storage lane from the aisle. This accessibility ensures quick and efficient pallet retrieval, reducing the time and labor required for order picking and fulfillment operations.

Improved Inventory Control

With push back racking, warehouses can achieve greater visibility and control over their inventory. The LIFO inventory management approach ensures that the most recently loaded pallets are readily accessible for picking and shipping, reducing the risk of stockouts and minimizing inventory spoilage. Additionally, push back facilitates accurate inventory tracking and rotation, allowing warehouse managers to monitor stock levels and expiration dates with precision.

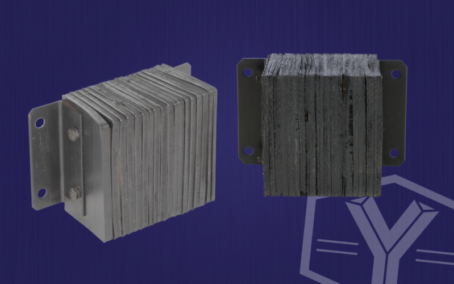

Durability and Reliability

Push back pallet rack systems are engineered for durability and reliability, providing long-lasting performance in demanding warehouse environments. Constructed from high-quality materials and designed to withstand heavy loads and frequent use, push back offers a robust storage solution that can withstand the rigors of daily operations. With proper maintenance and care, push back systems can provide years of dependable service, making them a sound investment for warehouse facilities.

Push back racking offers a versatile and efficient storage solution for warehouses and distribution centers seeking to maximize space utilization, streamline inventory management, and enhance operational efficiency. By combining dynamic storage capabilities with enhanced accessibility and inventory control, push back enables warehouses to optimize their storage space while maintaining the flexibility to adapt to changing business needs.

Practical Applications of Push Back Systems

Retail Inventory Management

In retail environments, where space optimization and efficient inventory management are paramount, push back racking systems play a crucial role. Retailers can utilize push back racks to store a wide range of products, from clothing and electronics to household goods and perishable items.

By leveraging the deep-lane storage configuration of push back systems, retailers can maintain ample stock levels while minimizing the footprint of their storage areas. This allows for more efficient use of retail floor space and ensures that products are readily accessible to customers and staff.

E-commerce Warehousing

With the exponential growth of e-commerce, warehouses and distribution centers face increasing pressure to maximize storage capacity and expedite order fulfillment processes. Push back systems provide an ideal solution for e-commerce warehousing, allowing for the efficient storage and retrieval of a diverse range of products.

Whether storing individual items or bulk inventory, e-commerce warehouses can benefit from the dynamic storage capabilities of push back systems, which enable quick and easy access to stored goods. This facilitates faster order processing and shipping, resulting in improved customer satisfaction and retention.

Cold Storage Facilities

In cold storage facilities, where temperature control is critical for preserving perishable goods, push back systems offer efficient storage solutions that minimize the risk of product spoilage. By utilizing push back racks in cold storage environments, facilities can optimize space utilization while maintaining strict temperature requirements.

The deep-lane storage configuration of push back systems allows for the storage of palletized goods in temperature-controlled environments, ensuring that perishable items remain fresh and safe for consumption. This is particularly beneficial for industries such as food and pharmaceuticals, where product integrity and shelf life are of utmost importance.

Pharmaceutical Industry

In the pharmaceutical industry, where stringent regulations and precise inventory control are paramount, push back racking systems offer invaluable storage solutions. Pharmaceutical companies can utilize push back to store a wide range of products, including medications, medical devices, and raw materials, while ensuring efficient rotation and inventory management.

With the ability to accommodate temperature-sensitive medications and comply with Good Manufacturing Practices (GMP), push back systems provide a reliable storage solution for pharmaceutical warehouses and distribution centers. The high-density storage configuration of push back allows pharmaceutical companies to maximize space utilization and optimize inventory management.

This enhances operational efficiency and regulatory compliance while ensuring the safe storage and timely distribution of critical medications, contributing to improved patient care and safety. Push back racking systems play a crucial role in maintaining the integrity of pharmaceutical inventory and facilitating the seamless flow of products within the supply chain.

Manufacturing and Production

In manufacturing and production facilities, where inventory management is essential for maintaining smooth operations, push back racking systems provide efficient storage solutions for raw materials, work-in-progress inventory, and finished goods.

By implementing push back racks in manufacturing environments, companies can optimize space utilization and improve inventory visibility, ensuring that materials and products are readily available for production processes. This streamlines workflow efficiency and reduces downtime associated with inventory retrieval and replenishment, ultimately enhancing overall productivity and profitability.

Third-Party Logistics (3PL) Providers

Third-party logistics providers (3PLs) play a crucial role in facilitating supply chain operations for businesses across various industries. Push back racking systems offer 3PLs versatile storage solutions that can accommodate the diverse needs of their clients.

Whether storing goods for short-term warehousing or managing long-term inventory storage, 3PLs can leverage push back racks to optimize space utilization and enhance inventory management capabilities. This enables 3PLs to provide cost-effective storage solutions to their clients while maintaining flexibility and scalability to accommodate fluctuating demand.

In summary, push back racking systems offer practical applications across a wide range of industries and storage environments, from retail and e-commerce warehousing to cold storage facilities, manufacturing, and third-party logistics providers. By maximizing space utilization, streamlining inventory management, and enhancing operational efficiency, push back systems provide versatile storage solutions that meet the diverse needs of modern businesses.

Push Back Racking Manufacturers

Interlake Mecalux, Inc.

Interlake Mecalux is a global leader in warehouse storage solutions, offering a wide range of push back racking systems designed to optimize space utilization and streamline inventory management. With a focus on innovation and reliability, Interlake Mecalux push back racks are trusted by businesses worldwide for their durability and efficiency.

Buckley Pallet Rack

Buckley pallet rack systems are known for their robust construction and versatility. As a leading manufacturer of push back racking, Buckley offers customizable solutions to accommodate various storage requirements, from small-scale operations to large distribution centers.

Frazier Industrial Company

Frazier Industrial Company is renowned for its expertise in engineering and manufacturing push back racking systems that maximize storage density while maintaining accessibility and ease of use. With a commitment to quality and customer satisfaction, Frazier push back racks are ideal for warehouses seeking efficient storage solutions.

UNARCO Material Handling, Inc.

UNARCO Material Handling is a trusted name in the material handling industry, known for its comprehensive range of storage solutions, including push back racking systems. UNARCO push back racks are designed to withstand heavy loads and rigorous warehouse environments, providing reliable storage solutions for businesses of all sizes.

Ridg-U-Rak, Inc.

Ridg-U-Rak specializes in the design and manufacture of push back racking systems that offer exceptional durability and performance. With a focus on engineering excellence and customer service, Ridg-U-Rak push back racks are tailored to meet the unique needs of each warehouse, ensuring efficient storage and inventory management.

Hannibal Industries, Inc.

Hannibal Industries is a leading provider of push back racking systems designed to optimize warehouse space and enhance operational efficiency. With a commitment to innovation and sustainability, Hannibal Industries push back racks are trusted by industry professionals for their quality and reliability.

Konstant Storage Systems

Konstant Storage Systems is recognized for its comprehensive range of storage solutions, including push back racking systems that are engineered for durability and performance. With a focus on customer satisfaction and continuous improvement, Konstant push back racks deliver efficient storage solutions for warehouses and distribution centers.

Penco Products

Penco Products offers a diverse portfolio of storage solutions, including push back racking systems designed to maximize space utilization and improve inventory management. With a legacy of innovation and reliability, Penco push back racks are trusted by businesses across various industries for their quality and durability.

Steel King Industries, Inc.

Steel King Industries is a leading manufacturer of push back racking systems known for their strength, versatility, and efficiency. With a focus on providing cost-effective storage solutions, Steel King push back are designed to withstand the demands of modern warehouse environments while maximizing storage capacity.

Advance Storage Products

Advance Storage Products specializes in the design and manufacture of push back racking systems that offer superior space utilization and operational efficiency. With a commitment to innovation and customer satisfaction, Advance Storage Products push back are trusted by warehouses and distribution centers worldwide for their reliability and performance.

Wrapping Up

In conclusion, push back racking systems stand as a versatile and efficient solution for warehouses and distribution centers seeking to optimize space utilization, streamline inventory management, and enhance operational efficiency. With their dynamic storage capabilities and ability to accommodate diverse industries such as retail, e-commerce, cold storage, manufacturing, and pharmaceuticals, push back racks offer unparalleled versatility and reliability.

By leveraging the benefits of push back systems, businesses can maximize their storage capacity, improve inventory control, and adapt to changing market demands with ease. Whether it's maximizing retail floor space or ensuring the safe storage of temperature-sensitive medications, push back systems prove instrumental in driving efficiency and productivity across various sectors of the industry.

Yankee Supply is your go-to destination for both new and used push back racking solutions. With a comprehensive inventory featuring top-quality systems, we cater to diverse warehouse needs and budgets.

Whether you're looking for brand-new push back racks to optimize your storage space or cost-effective, gently used options to enhance efficiency without breaking the bank, Yankee Supply has you covered. Trust us to provide reliable solutions that meet your requirements and exceed your expectations, ensuring seamless operations and maximum productivity.