Frequently Asked Questions About Counting Scales

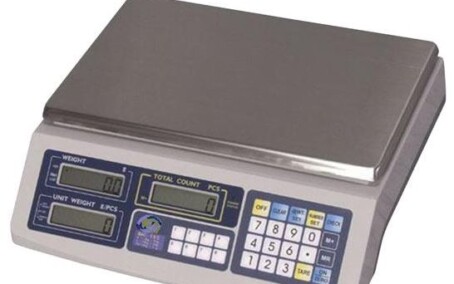

1. What are counting scales and how do they work?

Counting scales are specialized devices designed to count items based on their weight. They work by determining the weight of a sample piece, then calculating the number of items in a batch based on the total weight. These scales are commonly used in industries like manufacturing, retail, and shipping where large quantities of small items need to be counted quickly and accurately.

2. How accurate are counting scales?

The accuracy of your scales depends on the model, the precision of the load cell, and the method used for calibration. High-quality scales, such as those available at Yankee Supply, are designed for high precision and minimal error. With proper calibration and maintenance, you can expect accurate results with minimal variance.

3. What types of scales are best for counting small items?

For counting small items, scales that offer high-resolution displays and fine weight measurements are ideal. Scales with a higher count capacity and a minimum weight detection are often best suited for this purpose. At Yankee Supply, we offer a variety of scales designed specifically to count small, lightweight objects efficiently and accurately.

4. Can scales handle a wide range of products?

Yes, counting scales are versatile and can be used to count many different types of products, from small parts like nuts and bolts to more substantial items like fruits and vegetables. Whether you are counting screws, coins, or boxes, our scales can be calibrated to suit your needs.

5. What is the difference between counting scales and regular weighing scales?

Regular weighing scales are primarily used to measure the weight of a single item or the total weight of a batch. Counting scales, on the other hand, are designed to determine quantities of items based on weight and a known sample count. This makes scales ideal for high-volume environments where counting is required.

6. How do I calibrate a counting scale?

Calibrating a counting scale involves setting a known sample weight or quantity and ensuring that the scale can calculate the correct count based on that sample. Yankee Supply offers scales that come with easy-to-follow calibration instructions, and our customer support team is available to help you if needed.

7. What are the benefits of using counting scales in business operations?

Using counting scales can drastically improve efficiency and accuracy in inventory management, order fulfillment, and manufacturing processes. They help eliminate human error, speed up workflows, and provide reliable data for tracking quantities, all of which are essential for reducing costs and improving productivity.

8. Can I use scales for inventory management?

Yes, counting scales are excellent tools for inventory management. By using a scale to quickly determine the quantity of items in stock, you can maintain accurate inventory records, reduce stockouts or overstock situations, and optimize warehouse space.

9. How can I purchase counting scales from Yankee Supply?

You can browse our selection of scales on our website or contact our sales team for assistance. We offer competitive pricing and fast shipping on all our products. To get started or for any questions, call us at 800.232.7225 today.

Ready to streamline your counting process? Call Yankee Supply now at 800.232.7225!