Creating Efficient Storage Solutions With Mezzanine Decking

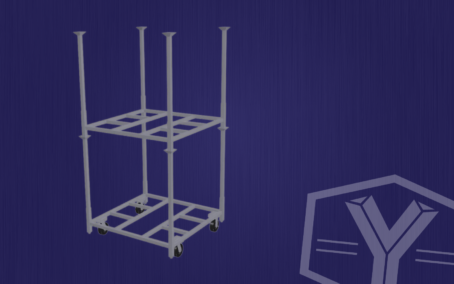

Industrial facilities often need to make better use of their vertical space, and that’s where mezzanine decking steps in as a practical solution. By adding mezzanine decking to existing structures, businesses can increase their usable footprint without the cost or downtime associated with major construction. Each installation opens the door to improved organization and streamlined workflows, as workers gain easier access to elevated inventory and equipment. Instead of shuffling materials across an already crowded floor, these decks let teams store essential items where they’re needed most.

Adapting To Different Applications

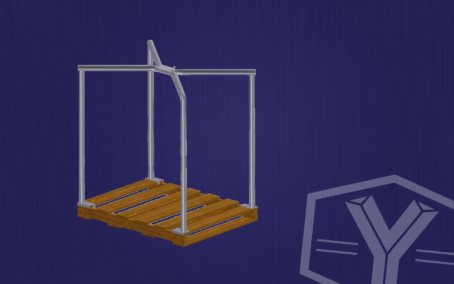

One of the strengths of mezzanine decking is its adaptability. From light-duty storage areas to robust sections designed for heavy machinery parts, mezzanine decks can be tailored to meet specific requirements. Companies can choose from a range of decking materials, such as steel grating or wood composite, to achieve the right balance between durability and cost-effectiveness. As operations evolve, layouts can be adjusted to handle changes in product lines, increasing inventory demands, or shifting project timelines. The flexibility of these decks ensures that growth never outpaces the storage capacity at hand.

Enhancing Safety And Accessibility

Safety remains paramount in industrial settings, and mezzanine decking contributes to a secure environment. Sturdy construction, reliable handrails, and slip-resistant surfaces help workers move about confidently when performing tasks above the main floor. Well-planned access points, combined with proper training, minimize potential hazards. Meanwhile, the elevated vantage point offers managers a clear line of sight, allowing them to observe production processes and quickly address potential issues. The result is a safer, more responsive workplace where everyone benefits from improved oversight.

Efficient Integration With Existing Systems

Many businesses worry that incorporating mezzanine decks will disrupt their established operations. However, installing decking often proves simpler than anticipated. Skilled technicians can complete much of the work with minimal downtime, and modular components make it easy to integrate these platforms into existing frameworks. Furthermore, mezzanine decking can align with conveyor belts, racking systems, or automated equipment. This synergy allows for seamless transitions between tasks, reducing delays and keeping output levels high.

Long-Term Value And Maintenance

Once mezzanine decking is in place, maintenance routines tend to be straightforward. Regular inspections, light cleaning, and minor repairs help preserve both safety and appearance. Over time, the efficiency gains and improved storage options justify the initial investment. By preventing overcrowding on the floor and minimizing wasted motion, these decks support ongoing productivity improvements. Facilities can adjust configurations as needed, ensuring that the solution remains relevant even as business demands shift.

Meeting Future Challenges

In an ever-changing market, adaptability can mean the difference between thriving and falling behind. Mezzanine decking not only solves immediate storage challenges but also positions organizations to meet future requirements. As product lines expand or technology evolves, these decks adjust accordingly, helping companies maintain a competitive edge. By optimizing vertical space and simplifying material handling, mezzanine decks turn formerly underutilized areas into valuable assets that contribute to long-term success in demanding industrial environments.