Efficiency, Precision, and Automation

Air cargo operations require precision, speed, and reliability to ensure the seamless transportation of goods. From automated guided vehicles (AGVs) to conveyor systems and robotic solutions, these advanced technologies enhance efficiency, minimize handling errors, and optimize workflow. Join us as we delve into the world of air cargo powered transfers and discover how they contribute to the success of the global air freight cargo industry.

Air cargo powered transfers encompass a range of technologies designed to automate and facilitate cargo movement within airports and aircraft. These systems utilize various mechanisms, including automated guided vehicles (AGVs), belt conveyors, robotic solutions, and powered roller decks. Key features of air cargo powered transfers include:

- Automation: Air cargo powered transfer systems automate cargo movement, reducing the reliance on manual labor and enhancing operational efficiency.

- Precision and Speed: These systems ensure precise positioning and speedy cargo transfer, minimizing handling time and expediting transportation.

- Integration: Air cargo powered transfers can be seamlessly integrated with other air cargo handling equipment, such as automated sorting, scanning, and tracking systems, to create a comprehensive and efficient workflow.

Elevating Operational Efficiency

Air cargo powered transfers significantly improve operational efficiency by automating cargo movement processes. These systems eliminate the need for manual handling, reducing human errors and enhancing overall workflow. By streamlining cargo transfers, air cargo powered transfer systems optimize operational resources and enable faster processing times, ultimately improving air cargo operations' overall productivity and performance.

Error-Free Handling

The automated nature of air cargo powered transfer systems greatly reduces the potential for handling errors. Automated guided vehicles (AGVs) and robotic solutions follow predefined routes and perform tasks precisely, minimizing the risk of mishandling or misrouting cargo. Additionally, these systems can be equipped with advanced scanning and tracking technologies, ensuring accurate identification and location of each cargo item throughout the transportation process.

Safety First

Air cargo powered transfer systems prioritize safety by minimizing the need for manual lifting and carrying of heavy cargo. These systems are designed with advanced safety features, including collision avoidance mechanisms, emergency stop systems, and safety sensors. By reducing physical strain and potential hazards, air cargo powered transfers create a safer working environment for personnel involved in cargo handling operations.

Adapting to Tomorrow's Needs

Air cargo powered transfer systems offer scalability and adaptability to meet evolving operational needs. As air cargo volumes fluctuate, these systems can be easily adjusted to accommodate changing demands. The modular design and flexibility of air cargo powered transfer technologies allow for seamless integration with existing infrastructure, making it easier to upgrade or expand cargo handling capabilities as required, it also allows you to customize your air cargo space for a seamless workflow.

AGVs - The Cargo Chauffeurs

Automated guided vehicles (AGVs) play a crucial role in air cargo-powered transfer systems. These self-driving vehicles can independently transport goods between different areas within airports, including storage facilities, freight terminals, and airplanes. AGVs have sensors, cameras, and navigation systems that empower them to maneuver complex surroundings and avoid barriers. They can manage a diverse array of cargo dimensions and loads, which aids in the smooth and effective flow of merchandise within the air cargo infrastructure.

Conveying Excellence

Conveyor systems play a critical role in air cargo operations, providing a continuous cargo flow between different processing points. These systems consist of motorized belts, rollers, and chutes that transport cargo along a predetermined path. Conveyor systems enable efficient sorting, screening, and loading of cargo, eliminating the need for manual lifting and reducing processing time. Integration with automated scanning and sorting technologies further enhances accuracy and efficiency in air cargo handling.

Robots - The Precision Payload Handlers

Robotic solutions have revolutionized the air cargo industry by automating complex tasks and processes. Robotic arms with advanced grippers and sensors can handle various cargo types, including irregularly shaped or fragile items. These robots can perform palletizing, de-palletizing, and stacking cargo, optimizing space utilization and ensuring efficient loading and unloading processes. Robotic solutions enable seamless integration with other automated systems, creating a synchronized and highly efficient air cargo workflow.

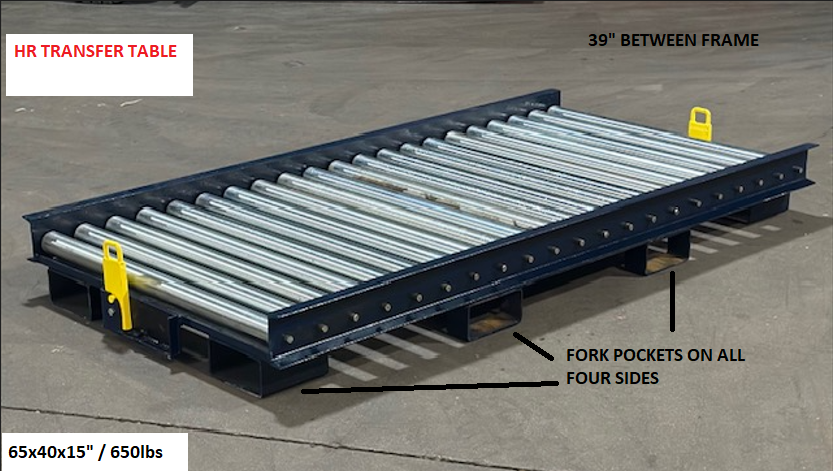

Powered Roller Decks - Cargo on the Move

Powered roller decks are motorized platforms with integrated roller systems facilitating cargo movement. These decks allow for smooth and controlled cargo transfer between different locations, such as cargo terminals and aircraft holds. The powered rollers ensure cargo slides smoothly along the deck, minimizing friction and reducing the physical effort required during handling. Powered roller decks are versatile and adaptable, accommodating various cargo sizes and configurations, and can be customized to fit specific operational requirements.

The Road to Efficiency

Air cargo-powered transfers revolutionize the industry by enhancing efficiency, reliability, and safety in cargo handling operations. By integrating automated guided vehicles, conveyor systems, robotic solutions, and powered roller decks, air cargo operations have become more streamlined, accurate, and adaptable. These advanced technologies optimize workflow, minimize handling errors, and expedite the transportation of goods, ultimately contributing to the success of the global air cargo industry.