Pallet Flow Racking: Streamlining Warehouse Operations

In the bustling landscape of warehouse management, efficiency reigns supreme. Picture a well-oiled machine, where every movement is choreographed with precision. At the heart of this operational symphony lies a crucial component: pallet flow racking.

Pallet flow racking, also known as gravity flow rack or flow through pallet racking, is a dynamic storage solution designed to optimize space utilization and streamline inventory management. Unlike traditional static shelving systems, flow through racking harnesses the power of gravity to facilitate the seamless movement of goods within the warehouse environment.

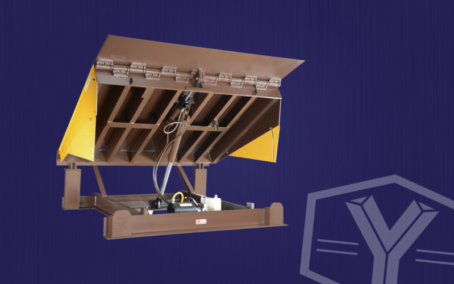

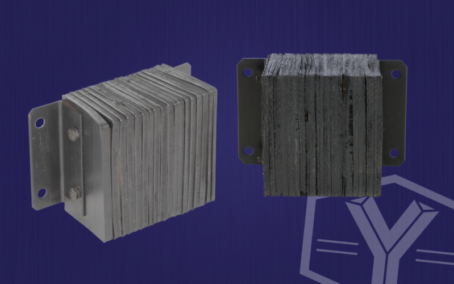

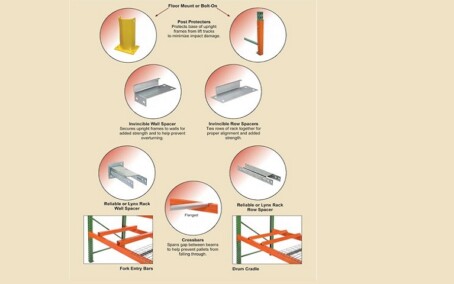

At its core, pallet flow racking operates on a simple yet ingenious principle. With inclined roller tracks or skate wheels installed within the rack structure, pallets are loaded from one end of the rack and gently glide down to the other end under the force of gravity. This gravity-fed process ensures FIFO (First In, First Out) inventory rotation, allowing for efficient stock replenishment and minimizing the risk of product obsolescence.

The design versatility of pallet flow racking makes it an ideal solution for a wide range of industries, from food and beverage to automotive and manufacturing. Whether dealing with perishable goods or bulky items, pallet flow racking offers unparalleled flexibility to adapt to diverse storage requirements.

But pallet flow racking is not merely a storage solution; it's a strategic asset that empowers warehouse managers to enhance productivity and maximize operational efficiency. By reducing travel time and minimizing manual handling, pallet flow racking accelerates order fulfillment processes, enabling businesses to meet customer demands with agility and precision.

As the demand for cost-effective and space-efficient storage solutions continues to soar, pallet flow racking emerges as a cornerstone of modern warehouse management practices. With its ability to seamlessly integrate with existing infrastructure and deliver tangible ROI, pallet flow racking proves to be a game-changer for businesses striving to stay ahead in today's competitive marketplace.

About Pallet Flow Rack

Pallet flow rack systems are engineered with inclined roller tracks or skate wheels integrated into the rack structure. This design allows pallets to be loaded onto one end of the rack and seamlessly glide down to the other end under the influence of gravity. This smooth flow of goods facilitates swift and precise stock replenishment, ensuring that products are consistently accessible for order fulfillment.

Advantages of Pallet Flow Rack

Enhanced Efficiency

Pallet flow racking streamlines warehouse operations by reducing travel time and minimizing manual handling. With goods flowing effortlessly through the system, employees can focus their efforts on value-added tasks, thereby enhancing overall productivity.

Space Optimization

By maximizing vertical space and eliminating the need for aisles between racks, pallet flow racking optimizes storage capacity within the warehouse. This compact design enables businesses to store a larger volume of inventory in the same footprint, effectively optimizing warehouse layout and reducing storage costs.

Inventory Rotation

Pallet flow racking ensures FIFO inventory rotation, prioritizing the use of the oldest stock first. This proactive inventory management approach helps prevent product spoilage and minimizes the risk of obsolescence, ultimately reducing waste and maximizing profitability.

Versatility

Pallet flow racking is highly adaptable and can accommodate a wide range of product types, sizes, and weights. From perishable goods to heavy-duty materials, pallet flow racking offers the flexibility to meet diverse storage requirements across various industries.

Improved Accessibility

With goods smoothly flowing through the system, products remain easily accessible for picking and replenishment operations. This enhanced accessibility boosts order fulfillment efficiency, allowing businesses to fulfill customer orders with greater speed and accuracy.

Applications of Pallet Flow Systems

Pallet flow systems offer versatile solutions that extend beyond traditional warehouse storage. Their adaptability and efficiency make them suitable for various practical applications across different industries. Let's explore some of these applications:

Efficient Order Fulfillment

In distribution centers and warehouses, where speed and accuracy are paramount, pallet flow systems play a crucial role in ensuring efficient order picking and fulfillment. By organizing products for easy access and optimizing storage space, pallet flow systems enable rapid retrieval of items, leading to shorter order processing times and improved customer satisfaction.

Cold Storage Solutions

Pallet flow systems are widely used in cold storage facilities to manage perishable goods effectively. With FIFO inventory rotation, pallet flow systems help maintain product freshness by ensuring that older stock is used first. This application is especially beneficial for industries such as food and beverage, pharmaceuticals, and healthcare, where maintaining temperature-controlled environments is essential.

Manufacturing and Production Lines

In manufacturing and production environments, where just-in-time (JIT) inventory management is critical, pallet flow systems facilitate seamless material handling and supply chain integration. By streamlining the flow of raw materials and components to production lines, pallet flow systems support lean manufacturing practices, minimize production downtime, and enhance operational efficiency.

Retail Distribution Centers

Retail distribution centers rely on pallet flow systems to manage large volumes of diverse products efficiently. By organizing goods for easy access and optimizing storage space, pallet flow systems enable retailers to maintain optimal inventory levels, reduce stockouts, and improve inventory turnover rates. This application is essential for meeting the dynamic demands of retail supply chains and ensuring on-time delivery to stores.

Automated Storage and Retrieval Systems (AS/RS) Integration

Pallet flow systems can be seamlessly integrated with automated storage and retrieval systems (AS/RS) to further enhance warehouse efficiency and productivity. By combining the advantages of both systems, businesses can achieve higher throughput rates, reduce labor costs, and improve inventory accuracy. This integration is particularly beneficial for high-volume distribution centers and manufacturing facilities with complex storage requirements.

Cross-Docking Operations

In cross-docking operations, where goods are transferred directly from inbound to outbound vehicles with minimal storage time, pallet flow systems play a vital role in facilitating smooth material flow and logistics operations. By optimizing space utilization and minimizing handling, pallet flow systems help expedite the transfer of goods, reduce transit times, and improve supply chain efficiency.

Overall, pallet flow systems offer a versatile and practical solution for a wide range of applications, including order fulfillment, cold storage management, manufacturing, retail distribution, and logistics operations. Their ability to streamline material flow, optimize storage space, and integrate with other warehouse technologies makes them indispensable assets for modern logistics and supply chain management.

Manufacturers of Pallet Flow Racking

When it comes to pallet flow racking, several reputable manufacturers specialize in designing and producing high-quality systems tailored to meet the diverse needs of warehouses and distribution centers. Here are some of the leading manufacturers in the industry:

UNEX Manufacturing, Inc.

UNEX Manufacturing, Inc. is a pioneer in the field of material handling solutions, offering a wide range of pallet flow racking systems designed to maximize storage density and efficiency. With a focus on innovation and customer satisfaction, UNEX provides customizable solutions to optimize warehouse operations.

Span-Track by UNEX

Span-Track by UNEX is a leading provider of dynamic pallet flow solutions designed to improve picking efficiency and streamline inventory management. With its durable and versatile roller track systems, Span-Track enhances warehouse productivity while reducing labor costs and space requirements.

Mallard Manufacturing Corporation

Mallard Manufacturing Corporation specializes in gravity flow solutions, including pallet flow racking systems engineered to enhance warehouse throughput and inventory control. With its innovative design and commitment to quality, Mallard offers customizable solutions to meet the unique requirements of every warehouse.

Flexpipe

Flexpipe is known for its innovative material handling solutions, including modular flow racking systems designed to optimize space utilization and improve workflow efficiency. With its flexible and customizable designs, Flexpipe helps businesses create efficient and ergonomic storage solutions.

Hy-Tek Material Handling, Inc.

Hy-Tek Material Handling, Inc. offers a comprehensive range of pallet flow solutions designed to streamline warehouse operations and maximize storage capacity. With its expertise in material handling systems, Hy-Tek provides customized solutions to meet the specific needs of each customer.

Frazier Industrial Company

Frazier Industrial Company is a leading manufacturer of structural steel gravity racking systems known for their durability, reliability, and versatility. With its commitment to engineering excellence, Frazier delivers innovative solutions to optimize warehouse space and enhance productivity.

Bastian Solutions

Bastian Solutions specializes in providing integrated material handling solutions, including pallet flow racking systems designed to improve warehouse efficiency and throughput. With its focus on automation and technology, Bastian Solutions offers cutting-edge solutions to meet the evolving needs of modern warehouses.

Creform Corporation

Creform Corporation offers flexible and modular flow racking systems designed to optimize storage space and improve material flow in warehouses and manufacturing facilities. With its innovative approach to material handling, Creform helps businesses increase efficiency and productivity.

FlexQube

FlexQube specializes in modular and customizable material handling solutions, including pallet flow systems designed to maximize space utilization and streamline warehouse operations. With its focus on flexibility and innovation, FlexQube offers tailored solutions to meet the unique needs of each customer.

Interroll Group

Interroll Group is a global provider of material handling solutions, including pallet flow systems designed to enhance warehouse efficiency and productivity. With its advanced technology and engineering expertise, Interroll delivers reliable and high-performance solutions to optimize material flow in warehouses worldwide.

Alternative Names for Pallet Flow Racking

Exploring the lexicon of warehouse storage solutions reveals a variety of alternative names for pallet flow racking, each reflecting distinct features and functionalities:

- Gravity Flow Racks

- Carton Flow Racks

- FIFO Racks (First-In-First-Out)

- Live Storage Racks

- Carton Live Storage

- Gravity Flow Shelving

- Roller Racks

- Flow Shelving

- Dynamic Racks

- Pallet Flow Racks

- Dynamic Storage Racks

- Case Flow Racks

- Flow Through Racks

- Pick-to-Light Racks

- Gravity Feed Racks

These alternative names capture the essence of pallet flow racking systems, highlighting their dynamic and gravity-driven nature, as well as their ability to optimize storage space and enhance material flow within warehouse environments.

In conclusion, pallet flow racking systems offer a versatile and efficient solution for optimizing warehouse storage and streamlining material handling processes. From enhancing order fulfillment efficiency to maximizing space utilization and ensuring product freshness in cold storage environments, gravity fed racking systems play a crucial role in modern supply chain management. With a wide range of applications across various industries and the support of reputable manufacturers, businesses can rely on flow racking to improve productivity, reduce costs, and meet the evolving demands of their operations. Embracing the innovative features and benefits of gravity flow racking enables businesses to stay competitive in today's dynamic marketplace while achieving operational excellence and customer satisfaction.